Discover more from Weapons and Strategy

The Army is funding two competitors to build a new, lighter, Abrams tank, dubbed Abrams X.

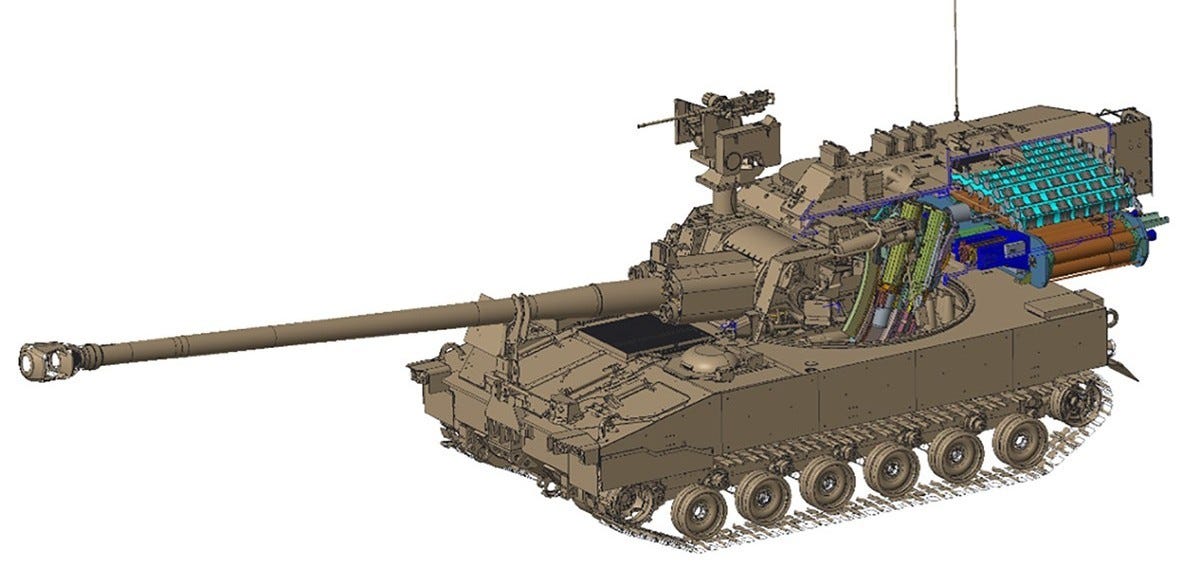

The new tank will feature a hybrid electric drive, have a reduced crew size, and will have an auto-gun loader.

Lessons from the Ukraine war have illustrated a number of problems with today's Abrams tank. So far the Russians have bagged eight Abrams, and an even bigger number of German Leopard's.

The Abrams is the world's heaviest main battle tank, 76.3 tons. Powered by a fuel-hungry 1,500 horsepower gas turbine engine, the tank has had problems operating in Ukraine, frequently getting stuck in the mud or rolling into craters made by enemy artillery.

The Russians have found that the Abrams can be knocked out by drones, especially the Lancet, destroyed by mines and found vulnerable to anti-tank weapons such as the Russian Kornet.

The Ukrainians complain that on humid days the tank's electronics fail, meaning it cannot be used in combat.

Each Abrams costs around $10 million out of the box. That does not include various add ons, such as Active Protection, nor does it include the cost of additional reactive armor which is expensive and adds substantial weight.

An ultra heavy tank also limits where it can operate, since the tank's weight and wide stance means it encounters difficulty with narrow bridges and congested urban streets.

The Abrams is not alone with this problem, but compared to other tanks it is the heaviest and widest.

For the past twenty to twenty-five years the Army has been working on a hybrid electric tank to replace both the gas turbine Abrams engine and diesel engine alternatives. A hybrid tank would have at least two electric motors, lithium batteries, and a diesel engine to generate electricity.

According to the Army, Abrams X will be 50% more fuel efficient than the Abrams. This huge fuel efficiency is achieved by dramatically reduced tank weight and by hybrid operating efficiency compared to the inefficient gas turbine power pack. The argument for hybrid electric is that it would allow tank operations to sometimes be "silent" (running solely on battery power). In those circumstances the tank's thermal signature would be far less, meaning that weapons that key on heat sources won't be threats when the engine is off.

From an operational and logistical point of view it would seem that a hybrid electric tank has a significant advantage.

But there are drawbacks too. One of them is the need for a large lithium battery pack. Battery packs are heavy and expensive and they also are dangerous because they can explode if hit by shrapnel or if a mine blows out the tank's bottom. While we don't know the size of the battery the Army will opt for, it will have to be big enough to power a heavy tank, meaning the battery could be a few tons in weight. This creates a vulnerability that does not exist today and raises questions on whether it makes sense to go in the hybrid direction.

In addition to exploding and burning batteries, an important question is field servicing. In warfare engines under great stress can be damaged or burn out and need to be replaced. In a modern modular power pack, it is possible to replace the entire assembly in a few hours, even in the field.

There are a few reasons why exchanging engines and other power components on a hybrid tank could be near to impossible. While the engine itself could be lifted out, it will be fitted with high voltage cables and connectors that require the battery to be safely disconnected and capacitors discharged before the engine can be removed. How this will be done in the field is an open question.

Even more troublesome are the electric motors that power the tank. These will be on the tank's underside, connected to the drive wheels. If the electric motors are damaged it is most likely the tank will have to be towed away, put on some kind of transit gurney, and sent to a repair depot with equipment capable of lifting the tank so it can be serviced.

Electric motors on tanks will be heavily stressed, far more than in any conventional vehicle. No one today can say anything about the long term reliability of an electric drive motor that will need to start and jump off multiple times on the battlefield. While electric motors are famous for generating a lot of torque, on a tank moving 67 tons or more on the battlefield, will stress the moving parts of these engines as never before.

There are many ancillary questions as well. Electric motors are heavy and need to be mounted on assemblies that can hold the weight and deal with the torque from them. This means that the tank's suspension will need considerable work to accept electric motor drives, and the drives themselves will add additional weight where you don't want it, on the road wheels. How this will translate on soft ground or in rainy or snowy conditions is hard to say, but it can mean that the tank will dig itself in more easily than a conventional drive train.

Electric and hybrid electric vehicles require specialized liquid, closed-loop cooling systems for the electronics. The Abrams today does not require a cooling system and other tanks, such as the Merkava, are air cooled. Leopard tanks require two radiators.

A lighter tank is an attractive alternative but powering it with electric motors and lithium batteries introduces its own problems and headaches that may make the Abrams X experiment just that, an experiment.

Other countries have been experimenting with hybrid electric power packs, but have not adopted them. Israel, beginning around 2016, developed a hybrid version of the Merkava tank, but it did not go in the hybrid direction. Its new Merkava 5 has a turbo-charged MTU diesel rather than a gas turbine.

Autoloader

While Russian tanks have had autoloaders for the tank's cannon since 1967, the US and UK have not adopted them. The Germans had planned for a future autoloader for the Leopard, but never implemented it.

An autoloader adds some mechanical and electrical complexity to a tank, but it can reduce the typical crew size from four to three. It also opens the door to various approaches to robotic or autonomous tanks in future.

Abrams X is supposed to have an autoloader and feature a three-person crew. The US has virtually no experience in autoloading 120mm shells.

Active Defense

Abrams X is planned to be equipped with a built-in Active Defense system.

There are very few Abrams tanks today with Active Defense systems and all of them are add-ons. The Army has purchased the Israeli Trophy system, but in relatively small numbers.

One of the questions for Active Defense systems is the ability to deal with drone strikes. Drones are typically slow moving when compared to missiles and rockets or tank rounds. On the modern battlefield drones can approach from virtually any angle and often are launched in batches. Any modern active defense system needs practical ways to destroy drones and would work best if networked with other tanks with active defense and non-tank air defenses. Whether that is part of the plan for Abrams X is not clear.

One limitation of a built in Active Defense system is that changes and upgrades are difficult once the system is physically embedded in a tank hull. Active Defense is still a young technology and in need of growth and improvement. As artificial intelligence gains a bigger foothold in military systems, tank protection is likely to be extremely important, especially since AI in a network can improve overall tank protection.

Will Abrams X Be Adopted

There is a lot of hype about Abrams X as a future main battle tank. There is little doubt that a lighter tank would work better in most conflicts, although light tanks bring their own vulnerabilities, especially susceptibility to drones and other "cheap" weapons. The case for a hybrid electric platform is one that remains to be proven, and despite some advantages hybrids also introduce operational, security and logistical issues that are far from being mitigated.

The US Army today is "woke" and one of the reasons to push hundreds of millions of dollars in research and development of the hybrid electric tank is related to ideology instead of necessity. In fact, any study of tank warfare in Ukraine is unlikely to support the case for a hybrid electric platform, since the main tank vulnerability is visual discovery of tanks by FPV Drones, not because they are heat sources.

There is no evidence the US Army has taken into account the lessons of the Ukraine war and worked on systems to kill drones that are playing havoc with US and European tanks.

A future system would include a networked capability to kill drones and counter air launched mines. Spending money on a hybrid electric platform is a mistake mostly because it avoids confronting the real issues on today’s and future battlefields.

Here's an alternative theory, based on years of watching government green initiatives: This is just a money grab. Someone involved in the decision making is poised to make a lot of money off of this effort.

One AFV contractor has already demonstrated an electric drive in a light tank. The US Army has done tank autoloaders at least 3 times. In addition, we were working on antidrone technology back in 2014. We just never got these thing funded or carried forward to completion. Current Pentagon leadership seems unlikely to get this pulled together. Our decision making processes, bureaucracy and technically illiterate leadership are the chief problems as is our penchant for “big programs with high-risk technical goals”.